About us

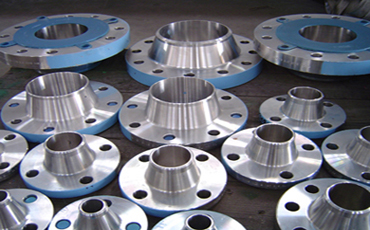

Quality Forge & Fitting

In the lifeline of industries, our fittings make sure pipeline in fact life lines of our industries are in perfect fit always. Carrying this responsibility on our shoulders, we at Quality Forge & Fitting always strive to make fittings & flanges that are excellent in quality,rich in material content and made to perfection that will last forever leaving a "Lasting impression on our customers "No wonder within a short span of time we have won many accolades from our satisfied customers from various core industries. Not to forget,all these efforts are only made possible by our able management,skilled man power,ethical business practice and financial stability.Here we promise you,"whenever you think of fitting and flanges "TRUST QUALITY FORGE RELIABILITY Just entrust us with the responsibility...we will deliver with quality,service and reliability.

Contact us

Products

Our Products

our advantages

-

Quality of the product

We ensure that the quality standards are met. Hence, as per customers requirement, we supply products of standard quality after going through various checking, testing, inspection & certification process.

-

Quality Raw Materials

All the material used for Manufacturing of fittings are tested for chemical & mechanical properties. They are identified & fully traceable from raw material stage to final product.

-

Checks & Controls

The system controls the quality of all incoming materials as per the raw material test certificate. Randomly checking in each size for chemical and physical properties at Government approved laboratory

-

Testing & Inspection

Quality Forge Fittings maintains strict dimensional standards by inspecting and testing equipmentwith strict adherence to the quality manual. All our finished material is inspected for quality after the first piece of a production.

-

Leading supplier

As ISO 9001:2008 Certified Company, we are the leading manufacturer and suppliers of all types of high quality Stainless Steel, Pipe Fittings, Butt weld and Forged Fittings and Flangers.

-

Certification

Fittings are supplied with test certificates as approved QAP which includes chemical composition, mechanical properties, hardness details of heat treatment and stamping details.

Clients say

The system controls the quality of all incoming materials as per the raw material test certificate of the material. Randomly checking in each size for chemical and physical properties at Government approved laboratory.- S S Umalkar, INDIA

During forming pressing forging and heat treatment process control system outlines inprocess checks and controls to be followed during heat treatment and testing.- George K Koshy, BAHRAIN

Suitables fixtures and templates are used to maintain dimensional accuracy necessary guages and callipers are calibrated periodically to maintain their acuuracy.- Ibrahim Alghailan, SAUDI ARABIA

Saudi Arabia

Saudi Arabia

Qatar

Qatar

Oman

Oman

Kuwait

Kuwait

Bahrain

Bahrain

UAE

UAE Mexico

Mexico

Canada

Canada

United States

United States

South Africa

South Africa

Singapore

Singapore

Malaysia

Malaysia

Sri Lanka

Sri Lanka

Australia

Australia

Brazil

Brazil

Venezuela

Venezuela

Bangladesh

Bangladesh

Turkey

Turkey

Netherlands

Netherlands

United Kingdom

United Kingdom

Iran

Iran

Nigeria

Nigeria