Quality Products

Long Weld Neck Standard Connection Flanges

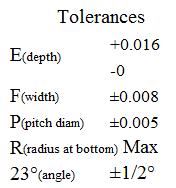

Dimensions of Ring-Joint Facings

| Nominal Pipe Size | Groove Dimensions | Diameter of Raised Portion K | |||||||||||||||

| 150 PSI | 300 PSI | 400 PSI | 600 PSI | 900 PSI | 1500 PSI | 2500 PSI | Groove # | Pitch Dia | Depth | Width | Radius at Bottom | 150 PSI | 300 400 600 PSI | 900 PSI | 1500 PSI | 2500 PSI | Depth |

| P | E | F | R | E | |||||||||||||

| ... | 1/2 | ... | 1/2 | ... | ... | ... | R11 | 1-11/32 | 7/32 | 9/32 | 1/32 | ... | 2 | ... | ... | ... | 7/32 |

| ... | ... | ... | ... | ... | 1/2 | ... | 12 | 1-9/16 | 1/4 | 11/32 | 1/32 | ... | ... | 2-3/8 | 2-3/8 | ... | 1/4 |

| ... | 3/4 | ... | 3/4 | ... | ... | 1/2 | 13 | 1-11/16 | 1/4 | 11/32 | 1/32 | ... | 2-1/2 | ... | ... | 2-9/16 | 1/4 |

| ... | ... | ... | ... | ... | 3/4 | ... | 14 | 1-3/4 | 1/4 | 11/32 | 1/32 | ... | ... | 2-5/8 | 2-5/8 | ... | 1/4 |

| 1 | ... | ... | ... | ... | ... | ... | 15 | 1-7/8 | 1/4 | 11/32 | 1/32 | 2-1/2 | ... | ... | ... | ... | 1/4 |

| ... | 1 | ... | 1 | ... | 1 | 3/4 | 16 | 2 | 1/4 | 11/32 | 1/32 | ... | 2-3/4 | 2-13/16 | 2-13/16 | 2-7/8 | 1/4 |

| 1-1/4 | ... | ... | ... | ... | ... | ... | 17 | 2-1/4 | 1/4 | 11/32 | 1/32 | 2-7/8 | ... | ... | ... | ... | 1/4 |

| ... | 1-1/4 | ... | 1-1/4 | ... | 1-1/4 | 1 | 18 | 2-3/8 | 1/4 | 11/32 | 1/32 | ... | 3-1/8 | 3-3/16 | 3-3/16 | 3-1/4 | 1/4 |

| 1-1/2 | ... | ... | ... | ... | ... | ... | 19 | 2-9/16 | 1/4 | 11/32 | 1/32 | 3-1/4 | ... | ... | ... | ... | 1/4 |

| ... | 1-1/2 | ... | 1-1/2 | ... | 1-1/2 | ... | 20 | 2-11/16 | 1/4 | 11/32 | 1/32 | ... | 3-9/16 | 3-5/8 | 3-5/8 | ... | 1/4 |

| ... | ... | ... | ... | ... | ... | 1-1/4 | 21 | 2-27/32 | 5/16 | 15/32 | 1/32 | ... | ... | ... | ... | 4 | 5/16 |

| 2 | ... | ... | ... | ... | ... | ... | 22 | 3-1/4 | 1/4 | 11/32 | 1/32 | 4 | ... | ... | ... | ... | 1/4 |

| ... | 2 | ... | 2 | ... | ... | 1-1/2 | 23 | 3-1/4 | 5/16 | 15/32 | 1/32 | ... | 4-1/4 | ... | ... | 4-1/2 | 5/16 |

| ... | ... | ... | ... | ... | 2 | ... | 24 | 3-3/4 | 5/16 | 15/32 | 1/32 | ... | ... | 4-7/8 | 4-7/8 | ... | 5/16 |

| 2-1/2 | ... | ... | ... | ... | ... | ... | 25 | 4 | 1/4 | 11/32 | 1/32 | 4-3/4 | ... | ... | ... | ... | 1/4 |

| ... | 2-/12 | ... | 2-1/2 | ... | ... | 2 | 26 | 4 | 5/16 | 15/32 | 1/32 | ... | 5 | ... | ... | 5-1/4 | 5/16 |

| ... | ... | ... | ... | ... | 2-1/2 | ... | 27 | 4-1/4 | 5/16 | 15/32 | 1/32 | ... | ... | ... | 5-3/8 | ... | 5/16 |

| ... | ... | ... | ... | ... | ... | 2-1/2 | 28 | 4-3/8 | 3/8 | 17/32 | 1/16 | ... | ... | ... | ... | 5-7/8 | 3/8 |

| 3 | ... | ... | ... | ... | ... | ... | 29 | 4-1/2 | 1/4 | 11/32 | 1/32 | 5-1/4 | ... | ... | ... | ... | 1/4 |

| ... | ... | ... | ... | ... | ... | ... | 30 | 4-5/8 | 5/16 | 15/32 | 1/32 | ... | ... | ... | ... | ... | 5/16 |

| ... | 3 | ... | 3 | 3 | ... | ... | 31 | 4-7/8 | 5/16 | 15/32 | 1/32 | ... | 5-3/4 | 6-1/8 | ... | ... | 5/16 |

| ... | ... | ... | ... | ... | ... | 3 | 32 | 5 | 3/8 | 17/32 | 1/16 | ... | ... | ... | ... | 6-5/8 | 3/8 |

| 3-1/2 | ... | ... | ... | ... | ... | ... | 33 | 5-3/16 | 1/4 | 11/32 | 1/32 | 6-1/16 | ... | ... | ... | ... | 1/4 |

| ... | 3-1/2 | ... | 3-1/2 | ... | ... | ... | 34 | 5-3/16 | 5/16 | 15/32 | 1/32 | ... | 6-1/4 | ... | ... | ... | 5/16 |

| ... | ... | ... | ... | ... | 3 | ... | 35 | 5-3/8 | 5/16 | 15/32 | 1/32 | ... | ... | ... | 6-5/8 | ... | 5/16 |

| 4 | ... | ... | ... | ... | ... | ... | 36 | 5-7/8 | 1/4 | 11/32 | 1/32 | 6-3/4 | ... | ... | ... | ... | 1/4 |

| ... | 4 | 4 | 4 | 4 | ... | ... | 37 | 5-7/8 | 5/16 | 15/32 | 1/32 | ... | 6-7/8 | 7-1/8 | ... | ... | 5/16 |

| ... | ... | ... | ... | ... | ... | 4 | 38 | 6-3/16 | 7/16 | 21/32 | 1/16 | ... | ... | ... | ... | 8 | 7/16 |

| ... | ... | ... | ... | ... | 4 | ... | 39 | 6-3/8 | 5/16 | 15/32 | 1/32 | ... | ... | ... | 7-5/8 | ... | 5/16 |

| 5 | ... | ... | ... | ... | ... | ... | 40 | 6-3/4 | 1/4 | 11/32 | 1/32 | 7-5/8 | ... | ... | ... | ... | 1/4 |

| ... | 5 | 5 | 5 | 5 | ... | ... | 41 | 7-1/8 | 5/16 | 15/32 | 1/32 | ... | 8-1/4 | 8-1/2 | ... | ... | 5/16 |

| ... | ... | ... | ... | ... | ... | 5 | 42 | 7-1/2 | 1/2 | 25/32 | 1/16 | ... | ... | ... | 9-1/2 | 1/2 | |

| 6 | ... | ... | ... | ... | ... | ... | 43 | 7-5/8 | 1/4 | 11/32 | 1/32 | 8-5/8 | ... | ... | ... | ... | 1/4 |

| ... | ... | ... | ... | ... | 5 | ... | 44 | 7-5/8 | 5/16 | 15/32 | 1/32 | ... | ... | ... | 9 | ... | 5/16 |

| ... | 6 | 6 | 6 | 6 | ... | ... | 45 | 8-5/16 | 5/16 | 15/32 | 1/32 | ... | 9-1/2 | 9-1/2 | ... | ... | 5/16 |

Dimensions in inches. Raised face height matches depth of groove.

Dimensions of Ring-Joint Facings

| Nominal Pipe Size | Groove Dimensions | Diameter of Raised Portion K | |||||||||||||||

| 150 PSI | 300 PSI | 400 PSI | 600 PSI | 900 PSI | 1500 PSI | 2500 PSI | Groove # | Pitch Dia | Depth | Width | Radius at Bottom | 150 PSI | 300 400 600 PSI | 900 PSI | 1500 PSI | 2500 PSI | Depth |

| P | E | F | R | E | |||||||||||||

| ... | ... | ... | ... | ... | 6 | ... | R46 | 8-5/16 | 3/8 | 17/32 | 1/16 | ... | ... | ... | 9-3/4 | ... | 3/8 |

| ... | ... | ... | ... | ... | ... | 6 | 47 | 9 | 1/2 | 25/32 | 1/16 | ... | ... | ... | ... | 11 | 1/2 |

| 8 | ... | ... | ... | ... | ... | ... | 48 | 9-3/4 | 1/4 | 11/32 | 1/32 | 10-3/4 | ... | ... | ... | ... | 1/4 |

| ... | 8 | 8 | 8 | 8 | ... | ... | 49 | 10-5/8 | 5/16 | 15/32 | 1/32 | ... | 11-7/8 | 12-1/8 | ... | ... | 5/16 |

| ... | ... | ... | ... | ... | 8 | ... | 50 | 10-5/8 | 7/16 | 21/32 | 1/16 | ... | ... | ... | 12-1/2 | ... | 7/16 |

| ... | ... | ... | ... | ... | ... | 8 | 51 | 11 | 9/16 | 29/32 | 1/16 | ... | ... | ... | ... | 13-3/8 | 9/16 |

| 10 | ... | ... | ... | ... | ... | ... | 52 | 12 | 1/4 | 11/32 | 1/32 | 13 | ... | ... | ... | ... | 1/4 |

| ... | 10 | 10 | 10 | 10 | ... | ... | 53 | 12-3/4 | 5/16 | 15/32 | 1/32 | ... | 14 | 14-1/4 | ... | ... | 5/16 |

| ... | ... | ... | ... | ... | 10 | ... | 54 | 12-3/4 | 7/16 | 21/32 | 1/16 | ... | ... | ... | 14-5/8 | ... | 7/16 |

| ... | ... | ... | ... | ... | ... | 10 | 55 | 13-1/2 | 11/16 | 1-3/16 | 3/32 | ... | ... | ... | ... | 16-3/4 | 11/16 |

| 12 | ... | ... | ... | ... | ... | ... | 56 | 15 | 1/4 | 11/32 | 1/32 | 16 | ... | ... | ... | ... | 1/4 |

| ... | 12 | 12 | 12 | 12 | ... | ... | 57 | 15 | 5/16 | 15/32 | 1/32 | ... | 16-1/4 | 16-1/2 | ... | ... | 5/16 |

| ... | ... | ... | ... | ... | 12 | ... | 58 | 15 | 9/16 | 29/32 | 1/16 | ... | ... | ... | 17-1/4 | ... | 9/16 |

| 14 | ... | ... | ... | ... | ... | ... | 59 | 15-5/8 | 1/4 | 11/32 | 1/32 | 16-3/4 | ... | ... | ... | ... | 1/4 |

| ... | ... | ... | ... | ... | ... | 12 | 60 | 16 | 11/16 | 1-5/16 | 3/32 | ... | ... | ... | ... | 19-1/2 | 11/16 |

| ... | 14 | 14 | 14 | ... | ... | ... | 61 | 16-1/2 | 5/16 | 15/32 | 1/32 | ... | 18 | ... | ... | ... | 5/16 |

| ... | ... | ... | ... | 14 | ... | ... | 62 | 16-1/2 | 7/16 | 21/32 | 1/16 | ... | ... | 18-3/8 | ... | ... | 7/16 |

| ... | ... | ... | ... | ... | 14 | ... | 63 | 16-1/2 | 5/8 | 1-1/16 | 3/32 | ... | ... | ... | 19-1/4 | ... | 5/8 |

| 16 | ... | ... | ... | ... | ... | ... | 64 | 17-7/8 | 1/4 | 11/32 | 1/32 | 19 | ... | ... | ... | ... | 1/4 |

| ... | 16 | 16 | 16 | ... | ... | ... | 65 | 18-1/2 | 5/16 | 15/32 | 1/32 | ... | 20 | ... | ... | ... | 5/16 |

| ... | ... | ... | ... | 16 | ... | ... | 66 | 18-1/2 | 7/16 | 21/32 | 1/16 | ... | ... | 20-5/8 | ... | ... | 7/16 |

| ... | ... | ... | ... | ... | 16 | ... | 67 | 18-1/2 | 11/16 | 1-3/16 | 3/32 | ... | ... | ... | 21-1/2 | ... | 11/16 |

| 18 | ... | ... | ... | ... | ... | ... | 68 | 20-3/8 | 1/4 | 11/32 | 1/32 | 21-1/2 | ... | ... | ... | ... | 1/4 |

| ... | 18 | 18 | 18 | ... | ... | ... | 69 | 21 | 5/16 | 15/32 | 1/32 | ... | 22-5/8 | ... | ... | ... | 5/16 |

| ... | ... | ... | ... | 18 | ... | ... | 70 | 21 | 1/2 | 25/32 | 1/16 | ... | ... | 23-3/8 | ... | ... | 1/2 |

| ... | ... | ... | ... | ... | 18 | ... | 71 | 21 | 11/16 | 1-3/16 | 3/32 | ... | ... | ... | 24-1/8 | ... | 11/16 |

| 20 | ... | 20 | ... | ... | ... | ... | 72 | 22 | 1/4 | 11/33 | 1/32 | 23-1/2 | ... | ... | ... | ... | 1/4 |

| ... | 20 | ... | 20 | ... | ... | ... | 73 | 23 | 3/8 | 17/32 | 1/16 | ... | 25 | ... | ... | ... | 3/8 |

| ... | ... | ... | ... | 20 | ... | ... | 74 | 23 | 1/2 | 25/32 | 1/16 | ... | ... | 25-1/2 | ... | ... | 1/2 |

| ... | ... | ... | ... | ... | 20 | ... | 75 | 23 | 11/16 | 1-5/16 | 3/32 | ... | ... | - | 26-1/2 | ... | 11/16 |

| 24 | ... | ... | ... | ... | ... | ... | 76 | 26-1/2 | 1/4 | 11/32 | 1/32 | 28 | ... | ... | ... | ... | 1/4 |

| ... | 24 | 24 | 24 | ... | ... | ... | 77 | 27-1/4 | 7/16 | 21/32 | 1/16 | ... | 29-1/2 | ... | ... | ... | 7/16 |

| ... | ... | ... | ... | 24 | ... | ... | 78 | 27-1/4 | 5/8 | 1-1/16 | 3/32 | ... | ... | 30-3/8 | ... | ... | 5/8 |

| ... | ... | ... | ... | ... | 24 | ... | 79 | 27-1/4 | 13/16 | 17/16 | 3/32 | ... | ... | ... | 31-1/4 | ... | 13/16 |

Dimensions in inches. Raised face height matches depth of groove.

Dimensional Tolerances B16.5 - 2003

| Threaded, Socket-Welding, Slip-On, Lap Joint, and Blind | Weld Neck | |||||

| Outside Diameter (1) | when the O.D. is 24" or less | ±1/16" | Outside Diameter (1) | when the O.D. is 24" or less | ±1/16" | |

| when the O.D. is over 24" | ±1/8" | when the O.D. is over 24" | ±1/8" | |||

| Inside Diameter | Threaded | within limites on boring gauge | Inside Diameter | = 10" | ±1/32" | |

| Socket-Welding, Slip-On and Lap-Joint | = 10"+1/32", -0" =12"+1/16",-0" | 12" through 18" | ±1/16" | |||

| = 20" | +1/8", -1/16" | |||||

| Outside Diameter of Hub (1) | = 12" | +3/32", -1/16" | Diameter of Contact Face | 1/16" Raised Face | ±1/32" | |

| = 14" | ±1/8" | 1/4" Raised Face Tongue & Groove Male, Famale | ±1/64" | |||

| Diameter of Contact Face | 1/16" Raised Face | ±1/32" | Diameter of Hub at Base (1) | when Hub Base is 24" or less | +1/16" | |

| 1/4" Raised Face Tongue & Groove Male, Famale | ±1/64" | when Hub Base is over 24" | ±1/8" | |||

| Diameter of Counterbore | Same as for Inside Diameter | Diameter of Hub at Point of Welding | NPS = 5" | +3/32", -1/32" | ||

| NPS = 6" | +5/32". -1/32" | |||||

| Drilling | Bolt Circle | ±1/16" | Drilling | Bolt Circle | ±1/16" | |

| Bolt Hole Spacing | ±1/32" | Bolt Hole Spacing | ±1/32" | |||

| Concentricity of Bolt Circle with Respect to Facing | NPS = 2 1/2", 1/32" max | Concentricity of Bolt Circle with Respect to Facing | NPS = 2 1/2" 1/32" max | |||

| NPS = 3", 1/16" max | NPS = 3" 1/16" max | |||||

| Thickness | = 18" | +1/8", -0" | Thickness | = 18" | +1/8", -0" | |

| = 20" | +3/16",-0" | = 20" | +3/16",-0" | |||

| Length Through the Hub (1) | = 18" | +1/8", -1/32" | Length Through the Hub | NPS = 4" | ±1/16" | |

| 5 = NPS = 10" | +1/16", -1/8 | |||||

| = 20" | +3/16", -1/16" | = 12" | +1/8", -3/16 | |||

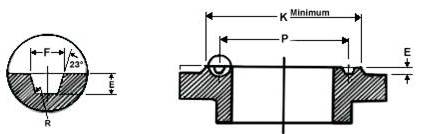

Welding Bevel Standards

for Wall Thickness "t" 3/16" to 3/4" incl. for Wall Thickness "t" greater than 3/4"

Contact us

Products

About Company

Quick Links

Products

Contacts

- 192/4, Pavapuri Appartment, 9th Street, Girgaon, Mumbai - 400 004, Maharashtra, India.

- qualityforge@gmail.com

- info@qualityforge.net

- +91 22 6639 4542

- +91 9619 352 777

Saudi Arabia

Saudi Arabia

Qatar

Qatar

Oman

Oman

Kuwait

Kuwait

Bahrain

Bahrain

UAE

UAE Mexico

Mexico

Canada

Canada

United States

United States

South Africa

South Africa

Singapore

Singapore

Malaysia

Malaysia

Sri Lanka

Sri Lanka

Australia

Australia

Brazil

Brazil

Venezuela

Venezuela

Bangladesh

Bangladesh

Turkey

Turkey

Netherlands

Netherlands

United Kingdom

United Kingdom

Iran

Iran

Nigeria

Nigeria